We ensure that all our assemblies are made from top quality component parts and hose. Certified to ISO 9001: 2015 we are committed to maintaining high standards of quality control.

Traceability is key, so for hoses out in the field, we provide a full traceability service to enable cross reference of the exact original spec, retaining records and reducing downtime. Whether the hose is offshore or onboard we can trace this using the retrospective certificate number to when this was made, to what specifications and when it was supplied on what purchase order. We do this by using the technique acid etching. We retain all records, and this ultimately reduces customers downtime.

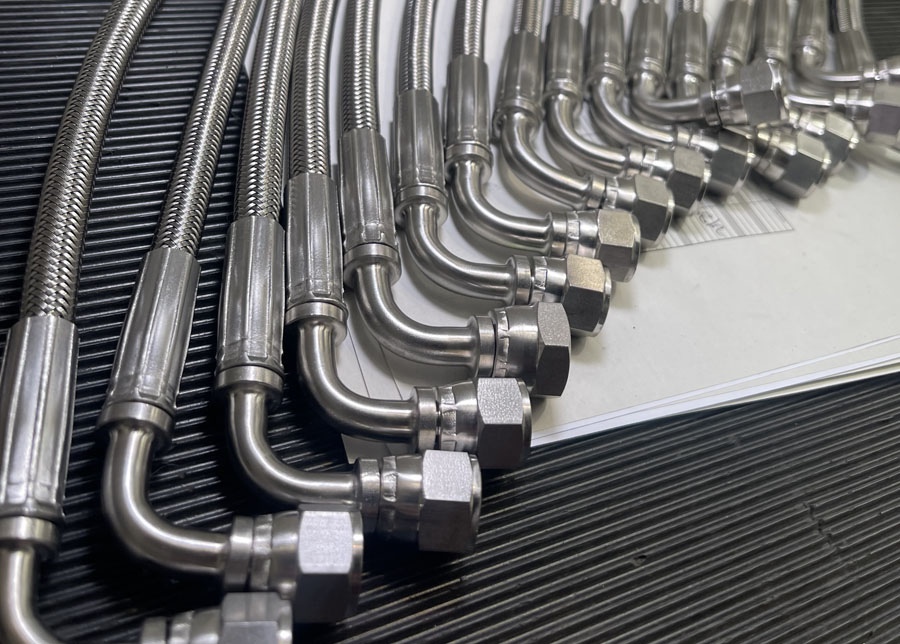

Hoses are assembled from vast stock holding of steel, brass and stainless-steel fittings and hose to meet application requirements.