Hydraulic System Calculations: Key Formulas for Improved Performance

/ 2

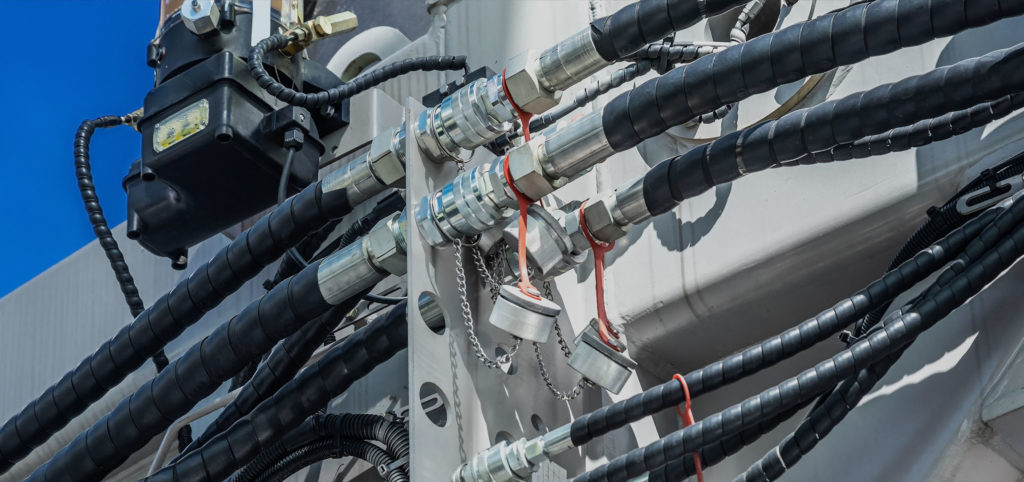

From manufacturing to construction, hydraulic systems are a key component across a multitude of industries.

With such importance on their performance, understanding necessary hydraulic calculations is vital to avoid unnecessary downtime, inefficient operations, and equipment failure.

Fluid Pressure (P): Understanding System Force

Pressure is a crucial factor in all hydraulic systems, representing the force exerted per unit area. Ensuring proper system pressure means your system operates with safe and efficient parameters.

Formula: P=FAP=AF

Where:

- PP = Pressure (PSI)

- FF = Force (Pounds)

- AA = Area (Square Inches)

Fluid Flow Rate (Q): Measure Fluid Volume

The flow rate measures the volume of fluid passing through a point per unit time and helps you to ensure the right amount of fluid is passing through.

Formula: Q=VTQ=TV

Where:

- QQ = Flow Rate (GPM)

- VV = Volume (Gallons)

- TT = Time (Minutes)

Fluid Power (Horsepower – HP): Improving Efficiency

Hydraulic systems rely on pressure and flow rate and so calculating horsepower allows you to gauge how much power there is for your system without overloading it.

Formula: HP=P×Q1714HP=1714P×Q

Where:

- HPHP = Horsepower

- PP = Pressure (PSI)

- QQ = Flow Rate (GPM)

Cylinder Area (A): Calculate Piston Surface Area

The area of a cylinder’s piston determines the force it can create, helping you to calculate how much force may be required for certain tasks.

Using Radius: A=π×R2A=π×R2

Using Diameter: A=π×D24A=4π×D2

Where:

- AA = Area (Square Inches)

- RR = Radius (Inches)

- DD = Diameter (Inches)

Cylinder Force (F): Determine Exerted Force

The force exerted by a hydraulic cylinder has to be calculated to make sure the cylinder can handle the required load of the system.

Formula: F=P×AF=P×A

Where:

- FF = Force (Pounds)

- PP = Pressure (PSI)

- AA = Area (Square Inches)

Cylinder Speed (v): Control Movement Speed

Cylinder speed controls how quickly pistons move and so the calculations are essential for optimising the timing of hydraulic systems.

Formula: v=0.3208×QAv=A0.3208×Q

Where:

- vv = Velocity (Feet per Second)

- QQ = Flow Rate (GPM)

- AA = Area (Square Inches)

Pump Output Flow (Q): Controlling Flow

Control the flow of hydraulic fluids using the below calculation to maintain correct pressure and rate of flow.

Formula: Q=n×d231Q=231n×d

Where:

- QQ = Flow Rate (GPM)

- nn = Speed (RPM)

- dd = Displacement (Cubic Inches per Revolution)

Pump Input Horsepower (HP): Pump Efficiency

Calculate the horsepower required to drive a pump to control flow rate and pressure and minimise energy waste.

Formula: HP=Q×P1714×EHP=1714×EQ×P

Where:

- HPHP = Horsepower

- QQ = Flow Rate (GPM)

- PP = Pressure (PSI)

- EE = Efficiency (Decimal Form)

Fluid Motor Torque (T): Motor Performance

Accurate torque calculations help you choose the motors that can handle the required load without compromising performance.

Formula: T=P×d6.2822T=6.2822P×d

Where:

- TT = Torque (Inch-Pounds)

- PP = Pressure (PSI)

- dd = Displacement (Cubic Inches per Revolution)

Understanding Hydraulic Calculations

Get in touch with Fluid Power Services today to review your hydraulic operations and improve your existing system’s performance.