5 Signs Your Industrial Pneumatic System Needs Immediate Attention

/ 1

Industrial pneumatic systems are the backbone of many manufacturing and processing operations. When they run smoothly, they’re efficient, reliable and cost-effective. When problems go unnoticed, however, small issues can quickly escalate into costly breakdowns, unplanned downtime and even safety risks.

Understanding the early warning signs of pneumatic system problems allows maintenance teams to act before failures occur. In this article, we’ll highlight five critical signs that your pneumatic system needs immediate attention and explain when issues can be handled through routine pneumatic system maintenance and when professional pneumatic troubleshooting is essential.

Why Early Detection Matters

Pneumatic systems often degrade gradually. Air leaks, contamination or compressor inefficiencies may not cause an immediate shutdown, but they steadily reduce performance and increase operating costs. Left unchecked, these issues can lead to major equipment failure and production delays.

Proactive maintenance and early intervention are far more cost-effective than reactive repairs.

#1: Sudden or Gradual Loss of Air Pressure

One of the most common warning signs is a noticeable drop in air pressure, either suddenly or over time.

What it means

- Loss of pressure can indicate:

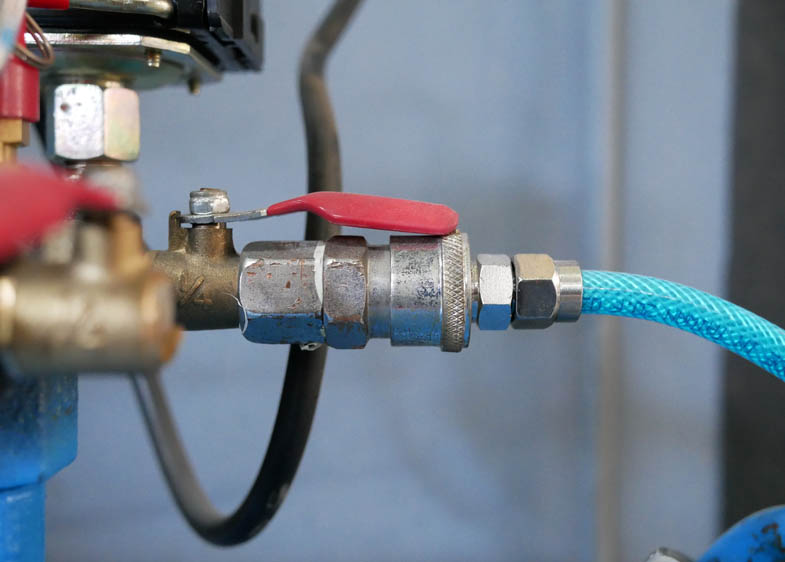

- Air leaks in hoses, fittings or seals

- Faulty regulators or valves

- Blockages or restrictions within the system

- Underperforming compressors

Even small pressure losses force compressors to work harder, increasing wear and energy consumption.

What you can check in-house

- Inspect hoses and connections for visible leaks

- Listen for hissing sounds during operation

- Check pressure gauges for inconsistent readings

When to call a professional

If pressure loss persists despite basic checks, or if it affects multiple machines, it’s time for expert pneumatic troubleshooting. System-wide pressure imbalances often point to deeper issues that require specialist diagnostics.

#2: Unusual Noises from the Pneumatic System

Operational noises in pneumatic systems should be fairly consistent, meaning new or worsening noises are a clear sign something isn’t right.

Common warning sounds

- Hissing: air leaks

- Knocking or banging: valve or actuator issues

- Excessive compressor noises: internal wear or strain

These sounds often signal early-stage industrial air compressor problems or component failure.

What you can check in-house

- Conduct routine listening inspections during operation

- Tighten loose fittings

- Check mounting points for vibration

When to call a professional

If noises originate from the compressor itself or continue after basic adjustments, professional inspection is crucial. Compressor failures are expensive and can halt production entirely if ignored.

#3: Rising Energy Costs or Increased Compressor Run Time

If your energy bills are creeping up without changes in production output, your pneumatic system may be the cause.

Why this happens

Inefficient systems waste compressed air through leaks, pressure drops, or poorly configured components. Compressors then compensate by running longer and harder, driving up electricity costs.

What you can check in-house

- Monitor compressor duty cycles

- Compare current energy usage with historical data

- Look for obvious leaks or pressure overcompensation

When to involve specialists

Persistent energy inefficiency often requires a full system assessment. Professional pneumatic system maintenance can identify hidden losses and optimise system performance, delivering long-term cost savings.

#4: Sluggish or Inconsistent Actuator Performance

Actuators that move slowly, inconsistently or fail to deliver sufficient force are a major red flag.

Possible causes

- Moisture or contamination in the air supply

- Blocked filters or dryers

- Faulty valves or worn seals

- Incorrect pressure settings

These issues can affect product quality, cycle times and safety.

What you can check in-house

- Inspect and replace filters as needed

- Drain moisture traps and receivers

- Verify correct lubrication levels

When professional help is needed

If actuator issues recur or affect multiple areas of the system, contamination may be widespread. At this point, expert pneumatic troubleshooting is essential to prevent further damage to valves and cylinders.

#5: Frequent Breakdowns or Repeated Component Failures

Repeated failures are rarely isolated incidents, usually signalling symptoms of a deeper problem.

Why this is serious

Constantly replacing the same parts without addressing the root cause leads to:

- Increased maintenance costs

- Reduced equipment lifespan

- Unplanned downtime

- Safety risks for operators

In-house vs professional repair

While replacing individual components may be manageable internally, repeated failures indicate that professional diagnostics are required. Specialists can identify underlying issues such as pressure instability, contamination, or compressor inefficiency.

When Can Pneumatic Issues Be Handled In-House?

Routine pneumatic system maintenance tasks often include:

- Visual inspections

- Leak detection

- Filter replacement

- Basic pressure tests

- Moisture draining

These proactive steps are vital for keeping systems running efficiently and preventing minor issues from escalating.

When Is Professional Intervention Essential?

Professional support is recommended when:

- Problems persist despite routine maintenance

- Multiple components fail repeatedly

- Industrial air compressor problems are suspected

- Energy consumption continues to rise

- Downtime risks outweigh the cost of expert intervention

Specialist engineers have the tools and experiences to diagnose system-wide issues quickly and accurately, minimising disruption to production.

The Value of Preventative Pneumatic Maintenance

Preventative maintenance isn’t just about avoiding breakdowns, it’s about improving efficiency, reliability and safety. Scheduled inspections and servicing help:

- Reducing energy waste

- Extend equipment lifespan

- Improve system performance

- Prevent costly production downtime

A well-maintained pneumatic system is an asset, not a liability.

Don’t Ignore the Warning Signs

Recognising the early signs of pneumatic system problems can save time, money and stress. Pressure loss, unusual noises, rising energy costs, sluggish performance and repeated failures all demand attention before they turn into major failures.

If your system is showing any of these signs, addressing them promptly through effective pneumatic troubleshooting and professional system maintenance can make all the difference.

For expert advice, inspections and maintenance support, Fluid Power Services can help keep your pneumatic systems operating reliably and efficiently, so your business stays productive.